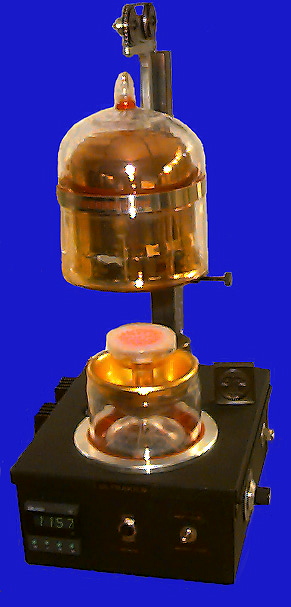

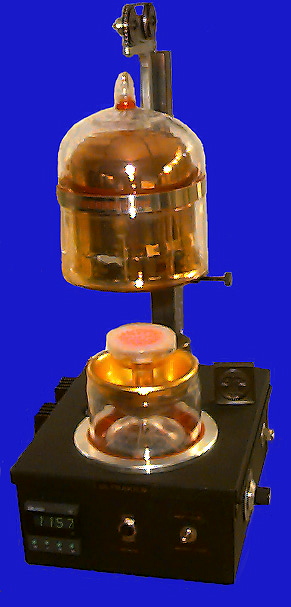

If you are a skilled enamelist, and wish to extend your

quality beyond that which is possible with the usual techniques used by

people in the trade, then I can not only build you one of these kilns (it

is hand-made, and not cheap-it took over 3 years to design), I can tell

you a few other things not generally known about the ways to manipulate

the material to achieve such results. For instance water purity requirements

and the special "sapphire" type of mortar and pestle needed for

grinding the glass. (You must start with lump form enamel, and it goes "off"

in a matter of minutes, even in ultrapure water). Details like this are

beyond the needs of most enamel workers, whose work would probably appall

you if you examined it under the 10 power binocular microscope I use for

my work. You can't really tell what you are doing without the magnification.

One of the main difficulties facing new entrants into this field is the

trouble you will have in finding proper lead-bearing enamels, which are

no longer made in the US, due to environmental concerns. Lead oxide in the

glass is necessary to give it a high index of refraction, for brilliance

or "fire". "Lead-free" enamels, as are now supplied

by T&T, are completely unsuitable for the finest work, and you must

find a source for lump form European materials, usually supplied in powder

form for hobbyists. Preground enamels are useless for fine work.